Have questions?

Request a consultation to discuss your hermetic sealing for electric vehicles or thermal management application needs with our team of experts.

Please Note: This Manufacturer Part Number is specific to an OEM specification. Customers MUST select the related specification from the right hand side. Selecting "Manufacturers Certification" will not lead to the correct paperwork being supplied as standard OEM certification is not available for this product.

In the Electric Vehicle industry, hermetic sealing for electric vehicles plays a critical role in protecting components such as contactors, relays, circuits, and rapid charging systems—especially in applications where thermal management and long-term reliability are essential.

Here are some of the key advantages:

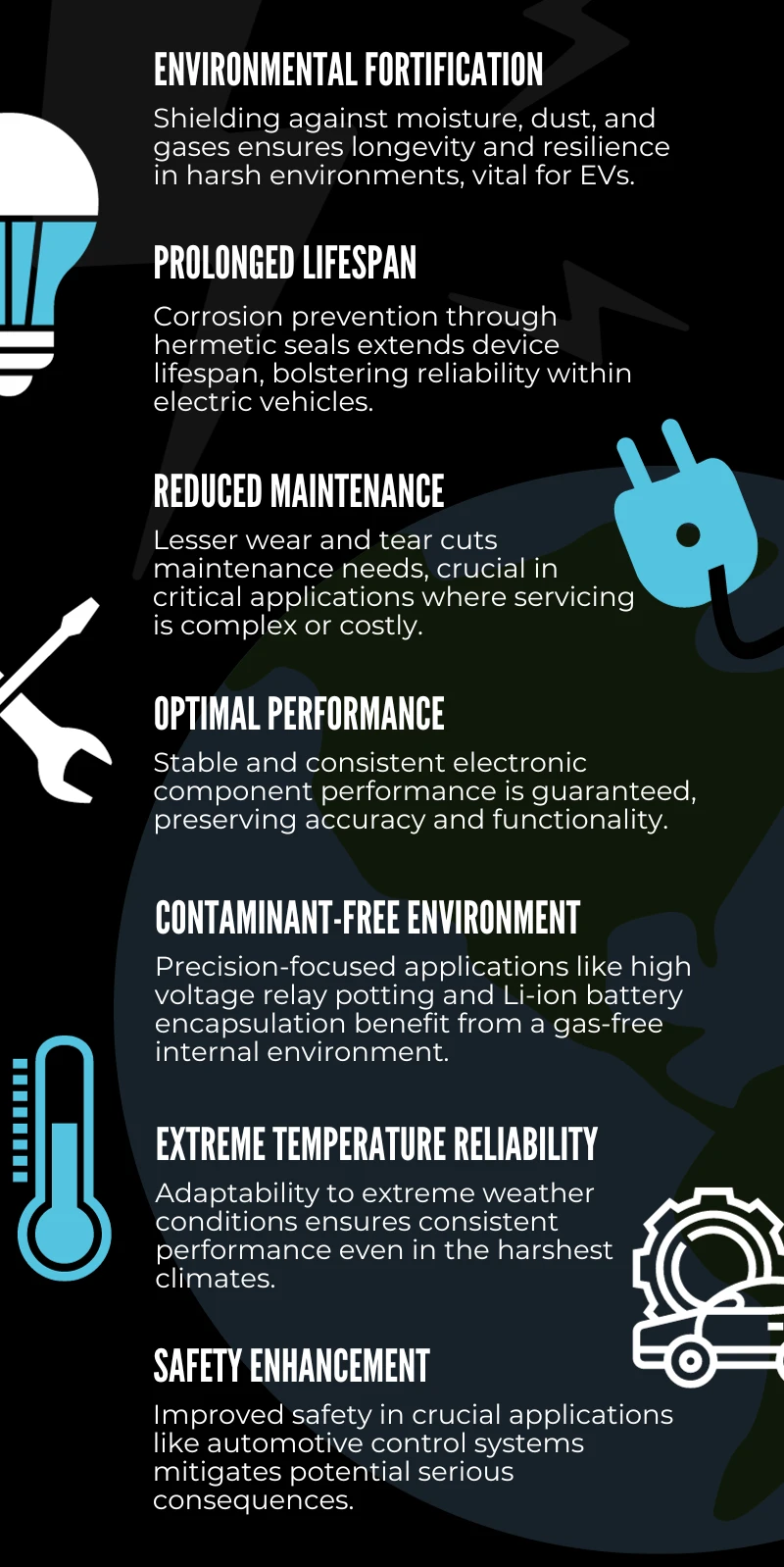

Hermetic sealing for electric vehicles, vital for effective thermal management, provides a high degree of protection against environmental factors such as moisture, dust, dirt, and gases. This is essential for electronic devices used in harsh or unpredictable environments, including electric vehicle and aerospace applications.

Hermetic seals prevent external elements from entering the device, which can lead to corrosion and damage over time. As a result, hermetically sealed electronic devices tend to have a longer lifespan and improved reliability within electric vehicles.

Hermetically sealed devices typically require less maintenance since they are less prone to wear and tear caused by environmental exposure. This is particularly important in critical applications where servicing may be difficult or costly.

Protection from environmental factors, crucial for effective thermal management, can lead to more stable and consistent performance of electronic components in electric vehicles. It helps maintain the functionality and accuracy of sensors, transducers, and other sensitive elements within the vehicle.

Hermetic sealing can create an inert internal environment, free from contaminants and gases, crucial for precise thermal management. This is particularly beneficial in applications like high voltage relay potting, staking of Li-ion battery cells, and encapsulation of motor windings.

Hermetic sealing is also essential in advanced battery thermal management applications, such as immersion-cooled EV batteries. By integrating hermetic feedthroughs, manufacturers can ensure a leak-proof interface between liquid coolant systems and high-voltage battery packs. This supports the development of safe, high-performance EV thermal management systems designed to operate under extreme load and environmental stress.

Modern hermetic feedthrough technologies are engineered to meet the rigorous demands of thermal management EV systems, providing durable protection for high-voltage components in electric vehicles. These technologies are used to hermetically seal electrical connections within battery packs, fuel pumps, and sensor housings—ensuring long-lasting performance in harsh automotive environments.

Solutions like direct-cast epoxy assemblies enable low-profile, lightweight integration by sealing components directly into customer-designed housings. Other innovations, such as SAE wire feedthroughs with integral connectors, allow for simplified installation while maintaining a reliable, impermeable seal.

Many of these advanced assemblies exceed industry-standard IP ratings, offering resistance to water, dust, and vibration. Rigorous helium leak testing further verifies their sealing integrity—making them ideal for use in EV thermal management systems that demand consistent protection across varying temperatures and operating conditions.

Hermetically sealed devices used in hermetic sealing for electric vehicles, essential for efficient thermal management, are well-suited for extreme temperatures due to weather which directly affect the performance of the electronic components in a vehicle.

Hermetic sealing can enhance safety in applications where failure could have serious consequences, such as in automotive control systems for electric vehicles.

Electric vehicles demand versatile hermetic sealing solutions depending on the component and its exposure to environmental factors. Common types include epoxy direct casting for high-integrity seals in sensors, radial O-ring seals for removable connectors, and custom molded connectors designed to meet specific dimensional and thermal performance requirements. These sealing types play a vital role in thermal management EV systems, particularly for protecting high-voltage components from moisture and heat.

Request a consultation to discuss your hermetic sealing for electric vehicles or thermal management application needs with our team of experts.

Shop the Thermal Management Solutions Kit from Resin Formulators.